Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction:

The super farad capacitor is one of the super capacitors. It is a special power supply between the capacitor and the battery. It is a special power supply because it can also store electric energy, most of which are used in the automotive field, such as high-power pulse demand, wind power pitch, power grid distribution terminals, small UPS, start stop systems, etc.

Product specification:

Project | characteristic |

working temperature | -40℃+65℃@2.7V |

| -40℃+85℃@2.3V | |

Storage temperature | -40℃+70℃ |

capacity | 100~600F |

| tolerance | 0+30% |

| Rated voltage | 2.7V |

| Surge voltage | 2.85V |

temperature characteristic | Capacity change from - 40 ℃ to 65 ℃: 20% of the initial measured value of △ c ∠ @ 25 ℃ Internal resistance change: 100% of the nominal value of △ ESR ∠ |

High temperature load life | Capacity change of 1500h load under operating temperature and rated voltage: 20% of △ c ∠ initial measured value @ 25 ℃ internal resistance change: 100% of △ ESR ∠ nominal value |

Normal temperature load life | 10 year capacity change of load under 25 ℃ and rated voltage: 20% of the initial measured value of △ c ∠ @ 25 ℃ internal resistance change: 100% of the nominal value of △ ESR ∠ |

Normal temperature cycle life | Capacity change after 500000 charge discharge cycles (from rated voltage to 1/2 rated voltage) at 25 ℃: 20% of the initial measured value of △ c ∠ @ 25 ℃ Internal resistance change: 100% of the nominal value of △ ESR ∠ |

| Storage life | It shall be placed under no load for two years at 25 ℃ to meet the requirements of high temperature load life |

| Steady state temperature | At 40 ℃, 90% RH and rated voltage, the load is 240h, meeting the requirements for high temperature load life |

seri | Rated voltage V | Capacity F | DC internal resistance m Ω | AC internal resistance m Ω | Leakage current uA72hrs | Weight g | D*L(mm) | Energy density (Wh/kg) | Power density (Wh/kg) |

| YKY | 2.7 | 100 | 12 | 8 | 0.3 | 20 | 22*45 | 5.1 | 7.6 |

| 2.7 | 200 | 10 | 6 | 0.7 | 36 | 30*50 | 5.6 | 5.1 | |

| 2.7 | 360 | 3.6 | 4 | 1.1 | 65 | 35*60 | 5.7 | 8.0 | |

| 2.7 | 400 | 3.2 | 2.8 | 1.0 | 70 | 35*60 | 5.8 | 8.1 | |

| 2.7 | 470 | 3.5 | 3 | 1.3 | 75 | 35*60 | 6.3 | 6.9 | |

| 2.7 | 500 | 3.4 | 2.9 | 1.3 | 80 | 35*67 | 6.3 | 6.7 | |

| 2.7 | 600 | 3.5 | 3 | 1.5 | 82 | 35*70 | 7.4 | 6.4 |

Product display:

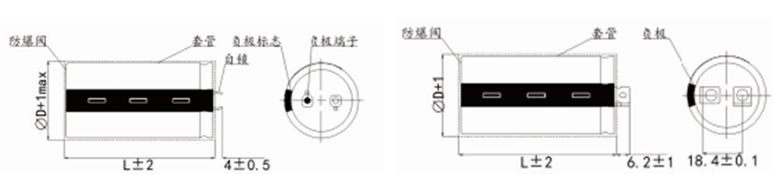

Product size:

Application field:

1. Portable devices: laptop, camera, PDA, digital camera, portable DVD, etc

2. Household appliances: 2-way radio, walkie talkie, electric toy, electric bicycle, emergency lighting

3. Military equipment

4. Medical treatment

5. Electric tools

Function of super farad capacitor:

1、 Its low internal resistance charging speed is very fast. 2、 It can be recycled for a long time, which is equivalent to a large power pack. The number of times it can be recycled is about 500000. It is highly reliable. 3、 The high current discharge capacity is strong, the energy conversion efficiency is very high, and there is almost no loss in the conversion process. 4、 The temperature tolerance is very strong. The super farad capacitor can withstand both high and low temperatures. 5、 No special control of charging circuit and discharging circuit is required. 6、 It is very convenient to detect the residual power of the super farad capacitor, which can be seen directly. Finally, the super farad capacitor is very environmentally friendly. Compared with other parts, the super farad capacitor is also a kind of green energy.

The super farad capacitor can be used for many applications. Here are two examples:

1. Flashlight

It is very frustrating to find that the flashlight is becoming more and more dim in an emergency when it is needed, because the battery life has expired. Even modern flashlights need to be fully charged for several hours, and the cycle life of the battery is very short. All this may become history. A flashlight that uses super capacitors instead of batteries as energy storage elements. It only takes 90 seconds to charge and has a cycle life of 500000 times.

2. DC screen energy storage system

As the power supply, the DC panel plays an important role in the power supply system of substations, power plants, large and medium-sized factories and mining enterprises. It is mainly used to supply power to the transmission mechanism of control, protection, communication equipment, automatic device operating machinery and regulating machinery. It can also be used as an independent emergency lighting power supply. Therefore, its performance and reliability directly affect the normal and safe operation of the entire power supply system.

Test method:

1. Electrostatic capacity tester

(1) Test principle

The electrostatic capacity of supercapacitor is measured by the method of constant current discharge of the capacitor and calculated according to the formula. C=It (U1-U2), where: C - electrostatic capacity, F; I - Constant discharge current, A; U1, U2 - voltage, V; Discharge time required from t-U1 to U2, S

(2) Test procedure

Charge the capacitor with a current of 100A until the capacitor is charged to the working voltage and the voltage is constant for 10 seconds, then discharge the capacitor with a current of 100A, taking U1 as 1.2VU2 as 1.0V, record the discharge time within the voltage range, the total circulating electrostatic capacity, and take the average

2. Storage energy

(1) Testing

The energy test of super capacitor is carried out by discharging the capacitor to 1/2 of the working voltage at constant power within the voltage range given by the capacitor. The output energy W of capacitor is obtained from the relationship between constant discharge power P and discharge time T, that is, W=P. T

(2) Test procedure

Charge the capacitor to the working voltage with a constant current of 100A, and then keep it constant until the charging current drops to the specified current (traction type 10A, starting type 1A). After 5 seconds of standstill, discharge the capacitor to 1/2 of the working voltage with a constant power, record the discharge time and calculate the value. Cycle 3 measurements and take the average value

3. Equivalent series resistance test (DC)

(1) Test principle

The internal resistance of the capacitor is measured according to the sudden change of voltage within 10ms after the capacitor disconnects the constant current charging circuit. In the formula: R-internal resistance of capacitor; U0 - Voltage before capacitor cut-off charging; Ui - Voltage within 10 ms after switching off charging; I - Cut off the current before charging.

(2) Measuring process

Charge the capacitor with a constant current of 100A, disconnect the charging circuit when 80% of the charging working voltage is reached, use a sampling machine to record the voltage change within 10 ms after the capacitor is powered off, calculate the internal resistance, repeat for 3 times, and take the average value.

4. Leakage current test

After the capacitor is charged to the rated voltage with a constant current of 100A, the capacitor is charged at this voltage for 30min at a constant voltage, and then it is left open for 72h. In the first three hours, record the voltage value every minute, and in the remaining time, record the voltage value every ten minutes.

Calculate the self discharge energy loss, SDLF=1 - (V/VW) 2, and the calculation time points are respectively 0.5,1,8,24,36,72h

Note: The voltage tester must have high input impedance to minimize the sound of the film.

Precautions:

Super capacitors cannot be used in the following states:

1) Temperature above nominal temperature

When the capacitor temperature exceeds the nominal temperature, the electrolyte will decompose, and the capacitor will generate heat, reduce capacity, increase internal resistance, and shorten service life.

2) Voltage exceeding rated voltage

When the capacitor voltage exceeds the nominal voltage, the electrolyte will decompose, and the capacitor will generate heat, reduce capacity, increase internal resistance and shorten life. Therefore, reducing the service voltage can improve the service life.

3) Loading of reverse voltage or AC voltage

1. The influence of ambient temperature on supercapacitors The service life of supercapacitors is affected by the service temperature. Generally, if the service temperature is increased by 10 ℃, the service life of supercapacitors will be shortened by half. Please try to use the supercapacitors in a low temperature environment lower than the service temperature. If it is used beyond the service temperature, it may cause sharp deterioration and damage of the characteristics. The use temperature of the super capacitor should not only confirm the ambient temperature and internal temperature of the equipment, but also confirm the radiation heat of the heater (power transistor, resistor, etc.) in the equipment, and the self heating temperature caused by ripple current. In addition, do not install the heater near the supercapacitor.

2. Please use the capacitor correctly according to the positive and negative pole marks.

3. Please avoid using super capacitors in the following environments.

a) The environment is directly splashed with water, salt water and oil, or is in the state of condensation and full of gas like oil or salt. b) An environment full of harmful gases (hydrogen sulfide, sulfurous acid, chlorine, ammonia, bromine, methyl bromide, etc.). c) Environment splashed with acidic and alkaline solvents. d) Direct sunlight or dusty environment. e) An environment subject to excessive vibration and shock.

4. Avoid overheating the capacitor during welding (for 1.6mm printed circuit board, the welding temperature shall be 260 ℃, and the time shall not exceed 5s).

5. Please avoid conducting circuit wiring between the outgoing poles of the super capacitor or between the solder joints of the connecting plate.

6. Overvoltage, exceeding the operating temperature range and other conditions beyond the rated conditions may cause the pressure valve to act and the electrolyte will be ejected. Therefore, please adopt the design method that has considered the possible occurrence of this abnormal condition.

7. During fast charging and discharging, voltage drop (also called IR drop) caused by internal impedance will be generated at the beginning of charging and discharging. Therefore, please adopt the design method that has considered the voltage change range.

8. If the terminals of power type high-capacity products (products above 10F) are short circuited during charging, hundreds of amperes of current will flow through, which is dangerous. Do not install or remove the battery in the charged state.

9. Do not put the capacitor into the dissolved solder, only stick solder on the guide pin of the capacitor. Do not let the welding rod contact the capacitor heat shrink tube.

10. Do not twist or tilt the capacitor forcibly after installation.

11. When the supercapacitor is used in series, there is a problem of voltage balance between individual capacitors